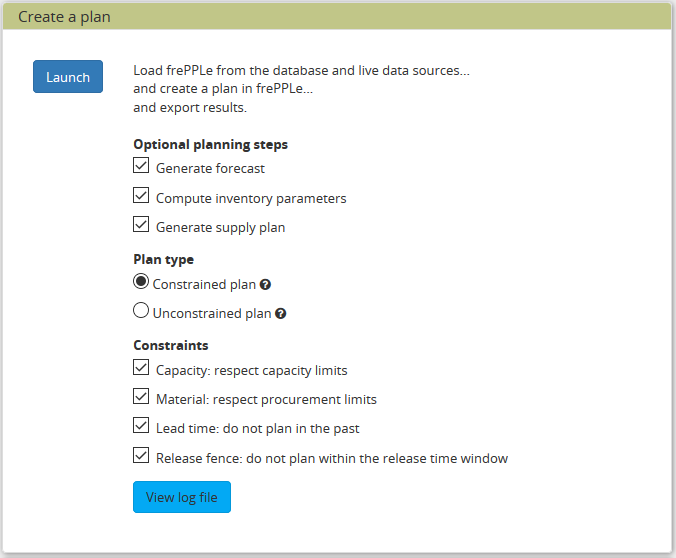

The plan generation screen can be found under the Admin/Execute menu.

This option runs the frePPLe planning engine with the input data from the database. The planning results are exported back into the database.

Optionally, on the Enterprise edition, the forecast and inventory planning modules can be run independantly prior to the plan generation.

The supply plan genaration box has to be ticked to generate purchase orders.

The forecast solver will calculate the forecast based on the historical demand for all (item, location, customer) intersections declared in the Forecast table.

The inventory planning solver will compute a safety stock and a reorder quantity for all buffers declared in the inventory planning parameters table.

Two main plan types can be distinguished, based on whether you want to see demand OR material, lead time and capacity problems to be shown.

In both the constrained and unconstrained plans you can select which constraints are considered during plan creation.

Reading the plan

The forecast calculated by the forecast solver is displayed in the forecast report and in the forecast editor.

The ROQ and safety stock values calculated by the inventory planning solver can be found in the DRP screen under Distribution/Distribution planning menu.

The generated distribution orders (when applicable) can be found under the Distribution/Distribution orders menu.

The generated manufacturing orders (when applicable) can be found under the Manufacturing/Manufacturing orders menu.

The generated purchase orders (when applicable) can be found under the Purchasing/Purchase orders menu.

Note that all the generated orders (purchase, distribution and manufacturing) will have status equal to “proposed” as they still have to be approved by the planner to be sent to your ERP system.