A bill of materials (BoM) is a document that describes the component products, the quantity of each component, and the process required to manufacture a product, including a routing and individual steps.

In Odoo, each product may have multiple BoMs associated with it, but a BoM can only be associated with a single product. A single BoM can, however, describe multiple variants of the same product.

Maken van een eenvoudige materiaallijst (BoM)

If you choose to manage your manufacturing operations using manufacturing orders only, you will define basic bills of materials without routings. For more information about which method of management to use, review the Getting Started section of the Manufacturing chapter of the documentation.

Before creating your first bill of materials, you will need to create a product and at least one component (components are considered products in Odoo). You can do so from , or on the fly from the relevant fields on the BoM form. Review the Inventory chapter for more information about configuring products. Once you have created a product and at least one component, select them from the relevant dropdown menus to add them to your bill of materials. A new bill of materials can be created from , or using the button on the top of the product form.

Under the Miscellaneous tab, you can fill additional fields. Sequence defines the order in which your BoMs will be selected for production orders, with lower numbers having higher priority. Version allows you to track changes to your BoM over time.

Routes toevoegen aan een materiaallijst (BoM)

A routing defines a series of operations required to manufacture a product and the work center at which each operation is performed. A routing may be added to multiple BoMs, though a BoM may only have one routing. For more information about configuring routings, review the chapter on routings.

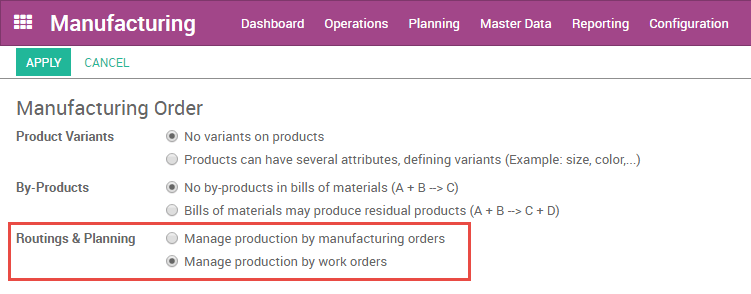

After enabling routings from , you will be able to add a routing to a bill of materials by selecting a routing from the dropdown list or creating one on the fly.

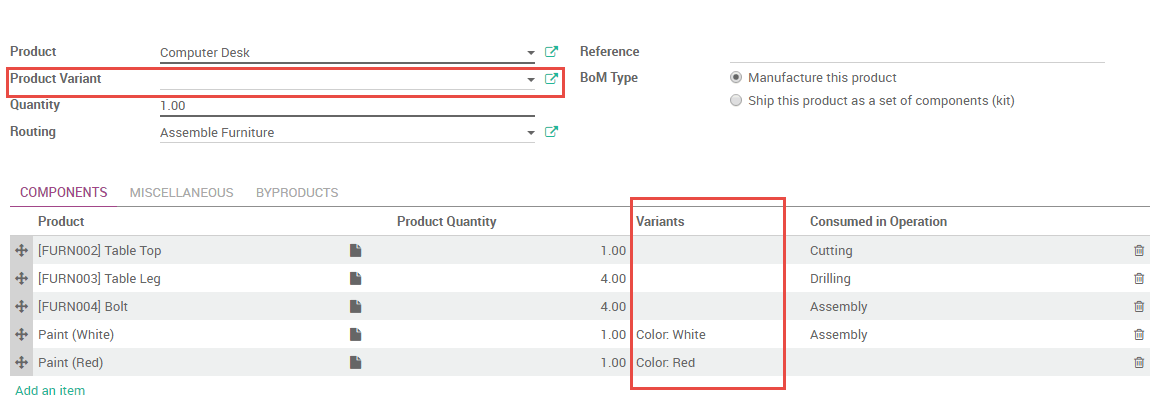

You may define the work operation or step in which each component is consumed using the field, Consumed in Operation under the Components tab. Similarly, you can define the operation at which the product will be produced under the Miscellaneous tab using the field Produced at Operation. If this field is left blank, the products will be consumed/produced at the final operation in the routing.

Adding Byproducts to a BoM

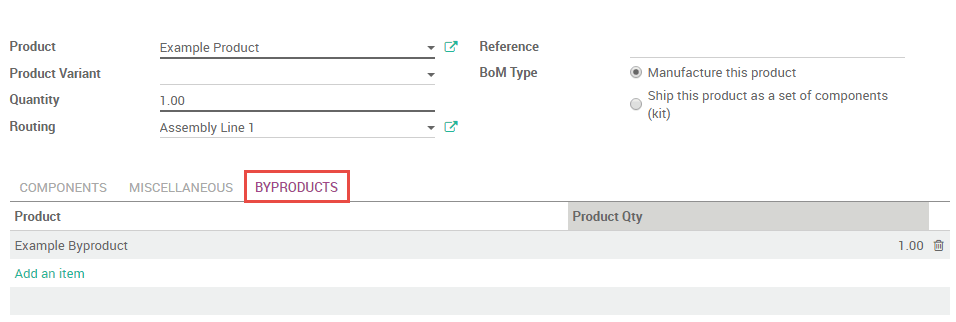

In Odoo, a byproduct is any product produced by a BoM in addition to the primary product.

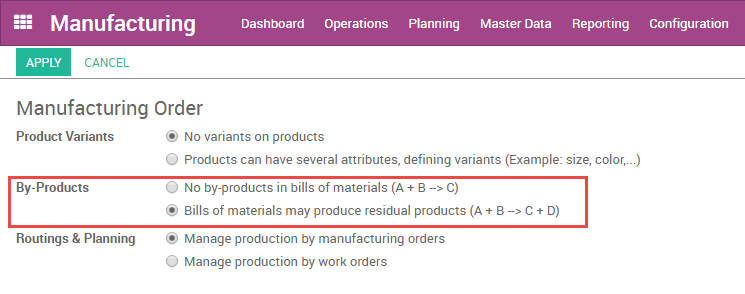

To add byproducts to a BoM, you will first need to enable them from .

Once byproducts are enabled, you can add them to your bills of materials under the Byproducts tab of the bill of materials. You can add any product or products as byproducts. Byproducts are produced in the same step of the routing as the primary product of the BoM.

Setting up a BoM for a Product With Sub-Assemblies

A subassembly is a manufactured product which is intended to be used as a component of another manufactured product. You may wish to employ sub-assemblies to simplify a complex BoM, to more accurately represent your manufacturing flow, or to use the same subassembly in multiple BoMs. A BoM that employs subassemblies is often referred to as a multi-level BoM.

Multi-level bills of materials in Odoo are accomplished by creating a top-level BoM and subassembly BoMs. Next, the procurement route of the subassembly product is defined. This ensures that every time a manufacturing order for the top-level product is created, a manufacturing order for each subassembly is created as well.

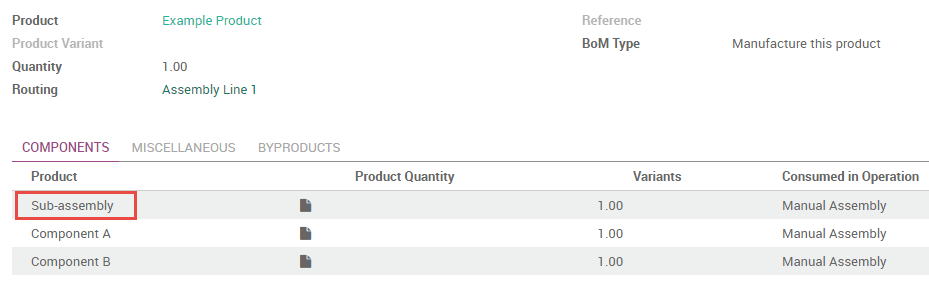

Configure the Top-Level Product BoM

To configure a multi-level BoM, create the top-level product and its BoM. Include any subassemblies in the list of components. Create a BoM for each subassembly as you would for any product.

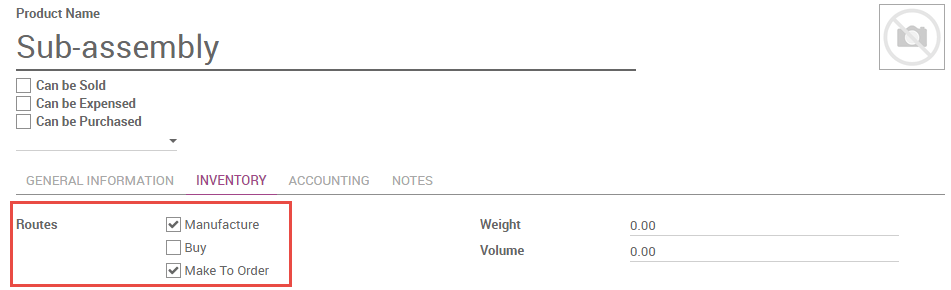

Configureer de productgegevens van de subassemblage

On the product form of the subassembly, you must select the routes Manufacture and Make To Order. The Manufacture route takes precedence over the Buy route, so selecting the latter will have no effect.

If you would like to be able to purchase the subassembly in addition to manufacturing it, select Can be Purchased. All other fields on the subassembly product form may be configured according to your preference.

Using a Single BoM to Describe Several Variants of a Single Product

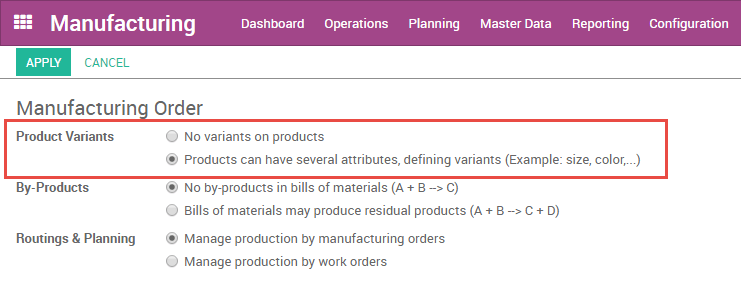

Odoo stelt u in staat om één materiaallijst te gebruiken voor meerdere varianten van hetzelfde product. Schakel varianten in via: menuselectie binnen Productie: Instellingen-> "Instellingen".

You will then be able to specify which component lines are to be used in the manufacture of each product variant. You may specify multiple variants for each line. If no variant is specified, the line will be used for all variants.

When defining variant BoMs on a line-item-basis, the Product Variant field in the main section of the BoM should be left blank. This field is used when creating a BoM for one variant of a product only.