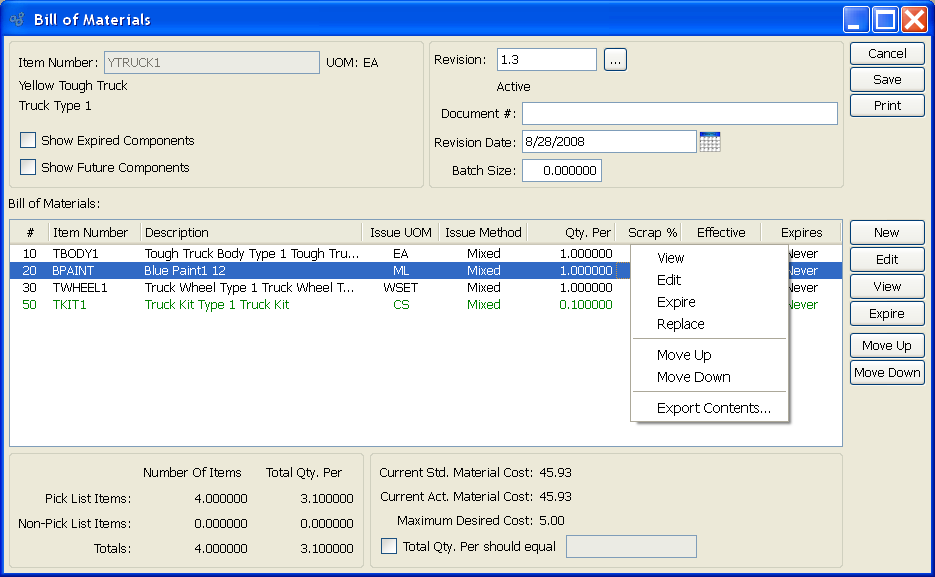

To create a new Bill of Materials, select the "Enter New Bill of Materials" option. The following screen will appear:

Note

Manufactured subcomponents will be displayed in greet text, to help distinguish them from other components.

When creating a new Bill of Materials, you are presented with the following options:

- Item Number

Enter the Item Number of the manufactured Item you want to create a Bill of Materials for.

- UOM

Inventory Unit of Measure.

- Show Expired Components

Select to display expired components in the "Bill of Materials" display. Expired components are components that have been expired from the Bill of Materials.

- Show Future Components

Select to display future components in the "Bill of Materials" display. Future components are components that will be added to the Bill of Materials at a future point in time.

- Revision

-

If Revision Control is enabled at your site, specify the Bill of Materials Revision Number you want to view. If none exists, simply enter a value to create one. The status of the Revision will also be displayed. The following statuses apply to Revisions:

- Active

-

This is the current, default Revision used for costing and Material Requirements Planning (MRP). Only one Revision can be active at the same time. Active Revisions may be modified. However, once a Revision becomes inactive, it may no longer be changed.

Tip

The active Revision becomes inactive when a pending Revision is activated. Inactive Revisions cannot be modified.

- Pending

This is a Revision that has never been used, but is under development or consideration. You may store multiple pending Revisions. When a pending Revision is entered in the "Revision" field, an ACTIVATE button will dynamically appear to the far right of the screen. Select the ACTIVATE button to convert a pending Revision to the active Revision.

- Inactive

This is a formerly active Revision. Inactive Revisions cannot be modified—only viewed. They are stored to provide historical, point-in-time build information, which may be used for various purposes throughout the application. For example, privileged users may select inactive Revisions when processing Work Orders or Purchase Orders. There is no limit to the number of inactive Revisions you may save.

- Document #

If desired, enter a document number to further identify the Bill of Materials.

- Revision Date

Indicates the date of the revision.

- Batch Size

Specify the Batch size.

- Bill of Materials

Display lists component Items for the Bill of Materials.

- Pick List Items

Displays the total number of component Items which are also Pick List Items. Items may be marked as Pick List Items on the Item master.

- Non-Pick List Items

Displays the total number of component Items which are not Pick List Items.

- Totals

Displays the total number of component Items.

- Current Std. Material Cost

Displays the current Standard Cost for the component Items. The displayed Cost includes all Standard Costs associated with the component Items. Any non-material Costs associated with manufactured subcomponents (e.g., Labor and Overhead) would also be included in this total.

- Current Act. Material Cost

Displays the current Actual Cost for the component Items. The displayed Cost includes all Actual Costs associated with the component Items. Any non-material Costs associated with manufactured subcomponents (e.g., Labor and Overhead) would also be included in this total.

- Maximum Desired Cost

Displays the maximum desired Cost for the component Items. The maximum desired Cost is defined on the Item master. It provides a visual guide to help determine whether component Item Costs—either Standard or Actual—have exceeded the maximum desired Cost.

- Total Qty. Per should equal

Select if you want to require the total Qty. Per units to equal a certain number. Enter the number you want the total Qty. Per units to equal. If selected, you will not be able to save the Bill of Materials until the total Qty. Per requirement is met. To remove the requirement, simply de-select this option.

To the far right of the screen, the following buttons are available:

- CANCEL

Closes the screen, returning you to the application desktop.

- SAVE

Saves the new Bill of Materials to the master list of Bills of Materials. Mac users may use COMMAND + S to save.

- ACTIVATE

-

Select to activate a pending Revision. This button will only be visible when a pending Revision number is entered in the "Revision" field.

Tip

When you activate a pending Revision, the currently active Revision will become inactive. Inactive Revisions cannot be modified.

Runs the report associated with this screen.

- NEW

Opens screen for creating a new component Item.

- EDIT

Enables you to edit highlighted components. The edit screen is the same as that for creating a new component—except that when editing, the fields will contain component information. Double-clicking on a component will also bring you to the editing screen.

- VIEW

Highlight a component and then select this button to reach a read-only view of the "Edit" screen.

- EXPIRE

Highlight a component and then select this button to expire the Item from the Bill of Materials.

Right-clicking on an Item in the Bill of Materials Item list enables you to select from the following menu options:

- View

Highlight a component and then select this button to reach a read-only view of the "Edit" screen.

- Edit

Enables you to edit highlighted components. The edit screen is the same as that for creating a new component—except that when editing, the fields will contain component information. Double-clicking on a component will also bring you to the editing screen.

- Expire

Highlight a component and then select this button to expire the Item from the Bill of Materials.

- Move Up

Highlight a component Item and then select this button to move the component up the Bill of Materials list. Sequence numbers are automatically adjusted to reflect the change in position.

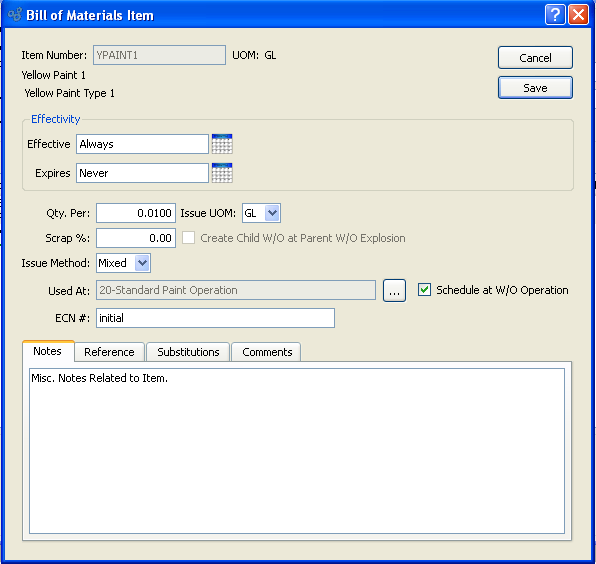

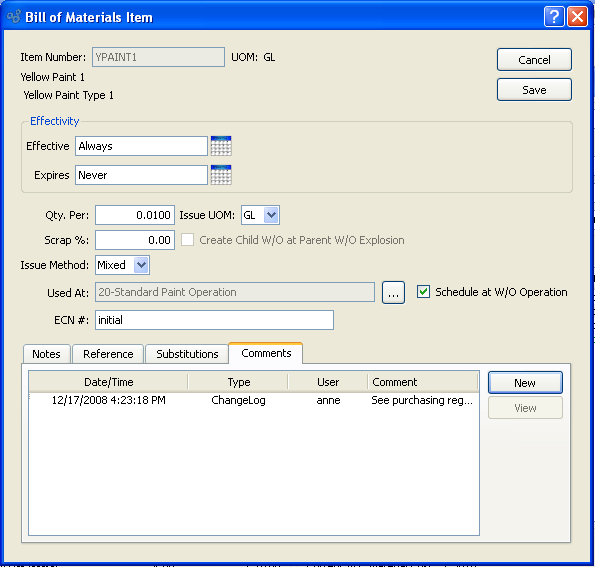

To add new components to a Bill of Materials, select the NEW button. The following screen will appear:

Tip

Bill of Materials component Items must have an Item Site defined to be valid.

When adding a new component Item to a Bill of Materials, you are presented with the following options:

- Item Number

Enter the Item Number of the Item you want to add to the Bill of Materials.

- UOM

Inventory Unit of Measure.

- Description

Description of Item.

- Effectivity

-

Specify the component's effectivity, using the following parameters:

- Effective

The system enables you to specify when a component can be used in a Bill of Materials. For example, the company's engineering department may be working on a new design for an existing Item—but that new design will not be available for use until a given date in the future. In this case, you can specify a future "effective" date to indicate when the component will be available for use.

- Expires

The system also enables you to specify when a component is planned to be obsoleted from (i.e., no longer used in) a Bill of Materials. As mentioned above, the company's engineering department may be working on a new design for an existing Item—but that new design will not be available for use until a given date in the future. In this case, the old component Item must be marked for "expiration" on the date when the new Item becomes effective. Setting this parameter will instruct the system to stop using the specified component on the date entered into this field.

- Qty. Per

Per: Specify the quantity of the component Item required per Bill of Materials. This is a required field.

- Issue UOM

Specify the Unit of Measure (UOM) you want to use when issuing Item quantity to Work Orders. Unless you specify an alternate UOM, the Inventory UOM will be used by default.

- Scrap %

Number entered should represent a percentage of material quantity that is additionally consumed as Scrap. This is a required field.

Tip

Using the "Create Child W/O at Parent W/O Explosion" option can greatly simplify the processing of Work Orders. If this option is not selected, child Work Orders will need to be created independently.

- Create Child W/O at Parent W/O Explosion

Select to create Work Orders for manufactured components when their parent Items are exploded. This option applies only to manufactured Items appearing as components on a Bill of Materials. If selected, a Work Order will automatically be created for the manufactured component when the parent Item is exploded. The impact on Work Order numbers will be visible. For example, a "-1" will be appended to the parent level Work Order and a "-2" to the child level Work Order—as in, #1061-1 and #1061-2. If this option is not selected, a child Work Order will not be created when the parent Item is exploded.

Note

The "Create Child W/O at Parent W/O Explosion" option will cause the creation of lower level Work Orders BOTH at Work Order explosion and also during the explosion that takes place during Master Production Scheduling (MPS) and Material Requirements Planning (MRP) runs.

- Issue Method

-

Method: Select one of the available issue methods:

- Push

Select if you want the component Item to be issued to Work Orders by a specific material issue transaction. Because a specific material issue transaction must be used, "Push" Items enable you to monitor material usage variances. Standard issue quantities are not automatically backflushed to Work Orders, as is true for "Pull" Items. If a component Item uses the "Push" issue method, you must manually issue quantities to Work Orders.

- Pull

Select if you want the component Item to be issued to Work Orders by a material backflush. "Pull" Items are automatically issued to Work Orders when Work Order Production is posted. Using the "Pull" issue method saves time, since materials do not need to be manually issued to Work Orders by a specific material issue transaction.

- Mixed

Select if you want the component Item to take upon itself the issue method applied to it initially—that is, either "Pull" or "Push." Assigning the "Mixed" issue method to a component Item gives you the flexibility of deciding on a Work-Order-by-Work-Order basis whether you want to assign the "Pull" or "Push" method to the component Item.

Note

You can define a default issue method for new Bill of Materials component Items at the system level.

- Used At

Specify which Operation the component is used at. Using the browse button located to the right of the field, select a Bill of Operations sequence number to identify which Operation the component is used at. Linking a component with an Operation will have certain effects. First, when posting Operations, components that are linked to a given Operation will be backflushed if the issue method for the components is either "Pull" or "Mixed" and the Operation is set to Auto Issue components. Secondly, Work Order paperwork, such as Routings, will show the relationship between linked Work Order Material Requirements and Work Order Operations.

Tip

If an Operation happens to have been expired on the current day, the Operation will still appear as an option when selecting "Used At" Operations. Once a day passes, however, the expired Operation will no longer appear as a "Used At" option on the BOM.

- Schedule w/ W/O Operation

Select to indicate that this component is not due until the Work Order Operation that will consume it is scheduled to begin. The scheduling of Operations is handled by the Execution Day indicator on the Bill of Operations item screen. For example, let's say we have an Operation with an Execution Day = 5. This means the Operation is scheduled to begin five days after the start date of the Work Order. Components scheduled with this Operation are due the day before the Operation starts—that is, on day four after the Work Order start date—to ensure they will be available when the Operation is scheduled to begin. If this option is not selected, then the component scheduling will be governed by the start and due dates set on the Work Order header.

Note

BOM-defined Substitutions are the only Substitutes which may be implemented during Work Order processing. To substitute a component Item on a Work Order, use the "Substitute" option found on the right-click menu of the Maintain Work Order Material Requirements screen.

- Notes

Enter additional Notes related to the Item.

To the far right of the screen, the following buttons are available:

- CANCEL

Closes the screen without inserting the component Item into the Bill of Materials, returning you to the previous screen.

- SAVE

Inserts the component Item into the Bill of Materials, automatically assigning it a sequence number.

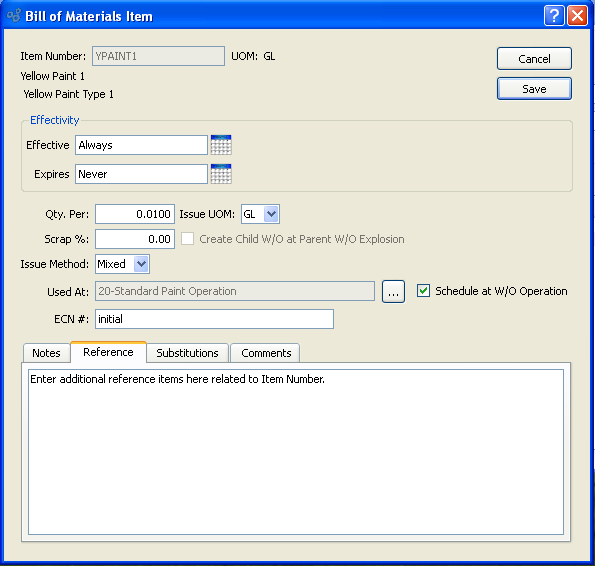

To add Reference information related to a BOM Item, select the "Reference" tab. The following screen will appear:

The Reference field can be used to identify any additional attributes associated with an Item.

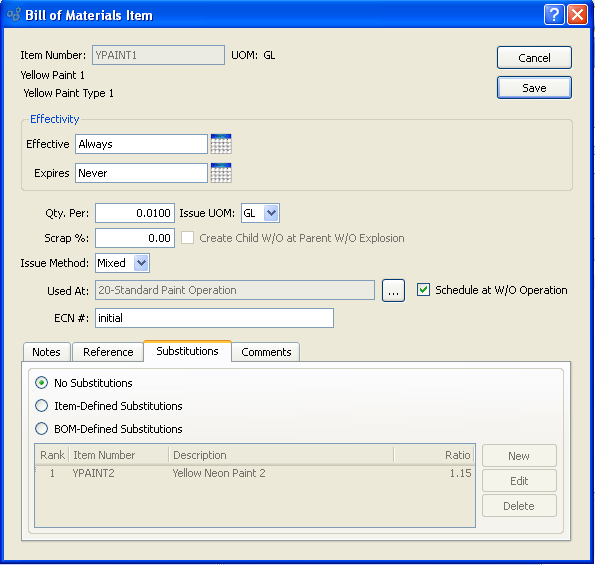

To add Substitution information related to a BOM Item, select the "Substitution" tab. The following screen will appear:

- Substitutions

-

Choose one of the following Item Substitution options:

- No Substitutions

Select if no Substitutions exist for the component Item.

- Item-Defined Substitutions

Select if Substitutions are defined on the Item master for the component Item. Selecting this option will not cause Item-defined Substitutions to display here. You are simply indicating that Item master level Substitutions do exist.

- BOM-Defined Substitutions

Select to define Item Substitutions at the Bill of Materials level.

Tip

To ensure Availability, a BOM-defined Substitution must be located in the same Site as the component Item it replaces. If the Substitute is located in a different Site, it will not be available for substitution.

To the far right of the screen, the following buttons are available:

- NEW

Opens screen for creating a new BOM-defined Substitution.

- EDIT

Enables you to edit a BOM-defined Substitution. Highlight the Item Substitute you want to edit and then hit the EDIT button—or double-click on the Item Substitute to enter the edit mode. The edit screen is the same as that for creating a new Item Substitute—except that when editing, the fields will contain existing information.

- DELETE

Highlight an Item Substitute and then select this button to remove the Item Substitute from the list.

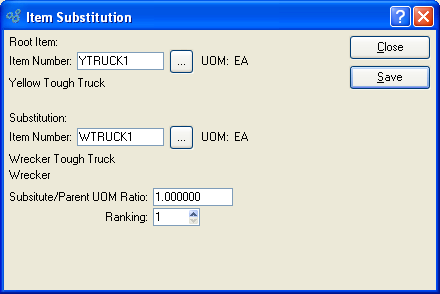

To create a new BOM-defined Substitution, select the NEW button. The following screen will appear:

When adding a new BOM-defined Substitution, you are presented with the following options:

- Item Number (Root Item)

Displays Item Number of specified component Item.

- UOM

Inventory Unit of Measure.

- Item Number (Substitution)

Enter the Item Number of the Substitute Item.

- UOM

Inventory Unit of Measure.

- Substitute/Parent UOM Ratio

Indicate the ratio between the Issue UOM for the specified BOM Item and the corresponding Issue UOM for the Substitute Item.

- Ranking

Select a number using the arrow buttons, or manually enter a value up to a maximum of 9. Enter the specified ranking order of the Item Substitute. You may assign the same ranking to multiple Items, if this is appropriate.

To the far right of the screen, the following buttons are available:

- CLOSE

Closes the screen, returning you to the previous screen.

- SAVE

Inserts the Item Substitution into the list of BOM-defined Substitutions.

To add Comments to a component Item, select the "Comments" tab at the bottom of the "Bill of Materials Item" screen. The following screen will appear:

- Comments

Display lists the date Comment entered, Comment Type, user who entered Comment, and a content preview.

To the far right of the screen, the following buttons are available:

- NEW

Opens screen for creating a new Comment.

- VIEW

Highlight a Comment and then select this button to reach a read-only view of the Comment.

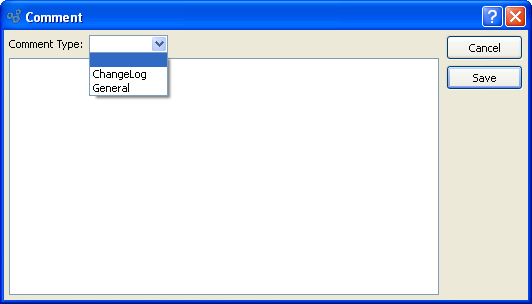

To create a new Comment, select the NEW button. The following screen will appear:

- Comment Type

-

Specify one of the following Comment Types from the drop-down list: ChangeLog or General.

Comment Types are used to categorize Comments. Once you have specified a Comment Type, you may type your Comment in the main text area. The text area features word-wrapping and scroll-bar support for longer Comments.

To the far right of the screen, the following buttons are available:

- CANCEL

Closes the screen without creating the Comment, returning you to the previous screen.

- SAVE

Creates the Comment and adds it to the list of Comments.

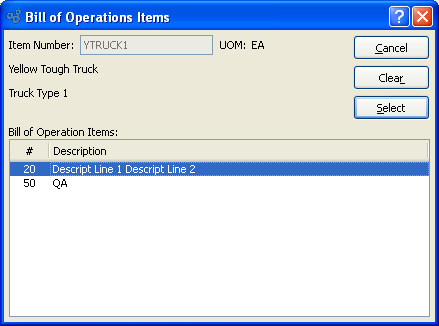

To link a Bill of Materials component to a Bill of Operations Item, select the browse button located to the right of the "Used At" field. The following screen will appear:

When linking Bill of Materials components to Bill of Operations Items, you are presented with the following options:

- Item Number

The component Item selected on the Bill of Materials screen will display here.

- UOM

Inventory Unit of Measure.

- Bill of Operation Items

Display lists Bill of Operations Items for the same manufactured Item whose Bill of Materials is being specified. Highlight the Operation you want to link the Bill of Materials Item to, then hit the SELECT button.

To the far right of the screen, the following buttons are available:

- CANCEL

Closes the screen without linking the Bill of Materials component to a Bill of Operations Item, returning you to the application desktop.

- CLEAR

Removes the link between a Bill of Materials component and a Bill of Operations Item if such a link has been made.

- SELECT

Links the Bill of Operations Item to the specified Bill of Materials component. Highlight the desired Bill of Operations Item before selecting the SELECT button.

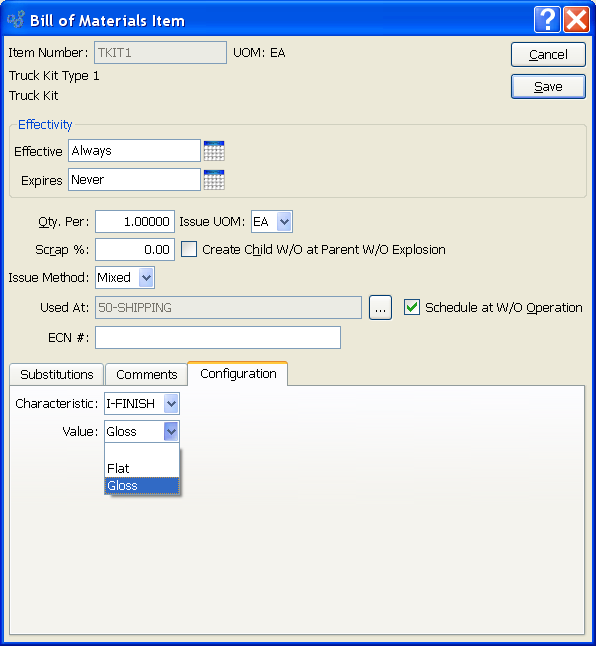

On a Bill of Materials, if the parent Item is a configured Item (i.e., configured Job Item or Reference Item), then you will have the option to link BOM Items to specific parent Item Characteristics. For example, let's say the parent Item has a Characteristic for paint finish with the values "Flat" and "Glossy". At the BOM Item level, you can specify whether the BOM Item goes with "Flat" or "Glossy". If you choose "Glossy" to associate with the BOM Item, then that means the BOM Item will be included as a material requirement whenever Orders call for the "Glossy" version of the parent Item. If no Characteristic association is made at the BOM Item level, then the BOM Item will always appear on Work Orders—regardless of the parent-level configuration selection. To associate Characteristics with a BOM Item, select the "Configuration" tab. The following screen will appear:

Note

You can learn more about Item configuration in xTuple ERP by reading the Assemble to Order (ATO) Configuration Topic.

When associating Characteristics with a BOM Item, you are presented with the following options:

- Characteristic

Select a Characteristic from the list of Characteristics. These Characteristics are Item Characteristics defined on the Item master for the parent Item on the Bill of Materials. Linking parent Characteristics to child BOM Items means the child Item will be included as a material requirement whenever Orders call for the same parent Item Characteristic.

- Value

Enter a value to associate with the selected Item Characteristic.