The Shop Floor Workbench offers enhanced labor tracking and streamlined Work Order processing for either Operations or Production posting environments. Its built-in Time Clock functionality ensures precise run-time reporting. Workbench users are required to clock-in to and clock-out of Work Orders.

Tip

The clock-in requirement applies only to Shop Floor Workbench users. If you don"t use the Workbench, no clock-in is required.

Note

This section description includes references to both Operations and Production posting. Operations posting is only allowed in the Manufacturing edition of xTuple ERP.

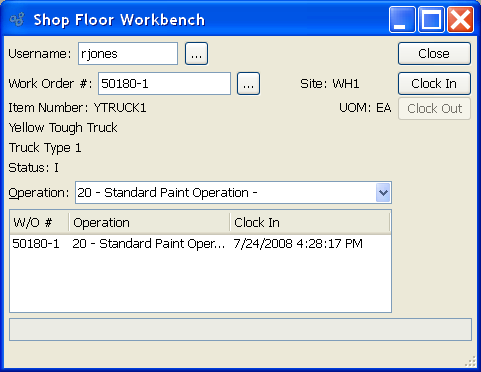

To access the Shop Floor Workbench, select the "Shop Floor Workbench" option. The following screen will appear:

Note

The Shop Floor Workbench must be configured for either Operations posting or Production posting. You may not use the Workbench for both methods simultaneously. To configure the method used by the Shop Floor Workbench, use the Configure W/O screen in the System module.

When accessing the Shop Floor Workbench, you are presented with the following options:

- Username

Enter the name of the user wanting to clock-in or clock-out of a Work Order. Once a username is entered, the display at the bottom of the screen will show all the Work Orders the user is currently clocked-in to.

Tip

At the system level, you can restrict a user's privileges so the Shop Floor Workbench is the only interface they see when they log in to the application.

- Work Order #

Enter the Work Order Number of the Work Order the user wants to clock-in to or clock-out of. Only released "R" and in-process "I" Work Orders may be processed using the Shop Floor Workbench.

Note

A Work Order must be released "R" before users may clock-in or clock out. The release of a Work Order occurs after the Work Order has been exploded.

- Site

Displays Site code automatically when Work Order Number is entered into "Work Order #" field.

- Item Number

Displays Item Number automatically when Work Order Number is entered into "Work Order #" field.

- UOM

Inventory Unit of Measure.

- Status

Displays Work Order Status automatically when Work Order Number is entered into "Work Order #" field. Only released "R" and in-process "I" Work Orders may be processed using the Shop Floor Workbench.

- Operation

If the Workbench is configured for Operations-posting, select an Operation from the list of Operations. Users are required to clock-in and clock-out of individual Operations. This allows run-time calculations to be performed on an Operation-by-Operation basis. A user may be clocked-in to multiple Operations simultaneously. Also, multiple users may be clocked-in to the same Operation. Whatever the case, the run-time clock starts when a user(s) clocks in to an Operation, and it stops when the user(s) clocks out.

To the far right of the screen, the following buttons are available:

- CLOSE

Closes the screen without clocking-in or clocking-out, returning you to the application desktop.

- CLOCK IN

Select to clock-in to the specified Work Order. When a user clocks-in to a Work Order, the run-time clock starts running from that point. The clock stops when a user clocks-out of the Work Order. The elapsed time—or "effort"—is used for labor reporting purposes. Users may only clock-in to Work Orders they are not already clocked-in to. However, users may clock-in to and clock-out of the same Work Order as many times as necessary. Each clock-in starts the run-time Time Clock; each clock-out stops it.

- CLOCK OUT

Select to clock-out of the specified Work Order. When selected, the run-time clock stops for the specified Work Order. The time elapsed since the user last clocked-in is added to the run time total for the Work Order. This run-time calculation is automatic and cannot be overridden—except by users who have override privileges. Users may only clock-out of Work Orders they are already clocked-in to. If the Workbench is configured for Operations-posting, the "Post Operations" screen will be presented immediately after the CLOCK OUT button is selected. By default, the "Scrap Work Order Material from W/O" screen will immediately follow the "Post Operations" screen.

Tip

Shop Floor Workbench users should only scrap top-level Items after they have posted production sufficient to cover the scrap quantity. For example, if a user assembles 10 top-level Items successfully but significantly damages the 11th, the user should post a quantity of 11 produced and then scrap one (i.e., 11 - 1 = 10).

- POST PRODUCTION

If the Workbench is configured for Production-posting, the Post Production screen will be presented immediately after this button is selected. The button will be hidden if the Workbench is configured for Operations-posting.