Issue Material transactions section.

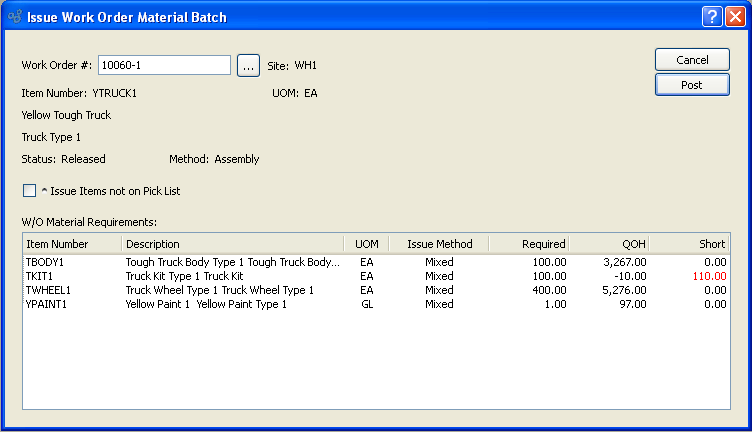

To issue Work Order Material Requirement Items simultaneously in a batch, select the "Issue W/O Material Batch" option. The following screen will appear:

When issuing Work Order Material Requirement Items in a batch, you are presented with the following options:

- Work Order #

Enter the Work Order Number of the Work Order whose component Items you want to issue in a batch.

- Site

Displays Site code automatically when Work Order Number is entered into "Work Order #" field.

- Item Number

Displays Work Order Item Number automatically when Work Order Number is entered into "Work Order #" field.

- UOM

Inventory Unit of Measure.

- Status

Displays Work Order Status automatically when Work Order Number is entered into "Work Order #" field.

- Method

Indicates whether selected Work Order is an Assembly or Disassembly Work Order.

- Issue Items not on Pick List

Select to indicate that non-Pick List Items should be backflushed as well.

- W/O Material Requirements

Display lists Work Order Material Requirements. The display is color-coded for ease of use. If an Item's issue method is "Pull," then that Item—and the entire row it sits on—will appear in blue type. The blue type indicates that the batch issue utility will not affect these Items. By definition, pulled Items are backflushed, not issued. However, if an Item's issue method is "Push," then that Item—and the row it sits on—will appear in black type. Rows with black type are affected by the batch issue utility. One other color may also appear. If the quantity required by the Work Order exceeds the Quantity on Hand—meaning there is an Inventory shortage—the value in the "Short" column will display in red.

Note

If you are issuing Lot/Serial Items to a Work Order, these cannot be issued automatically from a default Location. You must individually select and then distribute the desired Lot/Serial quantity.

To the far right of the screen, the following buttons are available:

- CANCEL

Closes the screen without issuing any materials to the selected Work Order, returning you to the application desktop.

- POST

Issues all pushed Work Order Material Requirements for the selected Work Order.

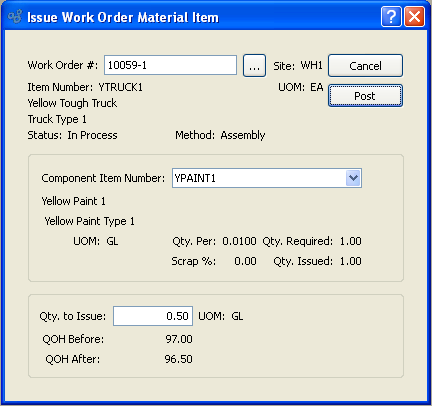

To issue Work Order Material Items individually, select the "Issue W/O Material Item" option. The following screen will appear:

When issuing Work Order Material Items individually, you are presented with the following options:

- Work Order #

Enter the Work Order Number of the Work Order whose individual component Item you want to issue.

- Site

Displays Site code automatically when Work Order Number is entered into "Work Order #" field.

- Item Number

Displays Item Number automatically when Work Order Number is entered into "Work Order #" field.

- UOM

Inventory Unit of Measure.

- Status

Displays Work Order Status automatically when Work Order Number is entered into "Work Order #" field.

- Method

Indicates whether selected Work Order is an Assembly or Disassembly Work Order.

- Comp. Item Number

Select one of the specified Item's component Items whose issue method is "Push" or "Mixed."

Note

If the "Comp. Item Number" list contains no component Items, this means that the issue method for all the component Items is "Pull." Only Items with the issue method of "Push" or "Mixed" will appear in the menu.

- UOM

Issue Unit of Measure.

- Qty. Per

Displayed value represents the quantity of the component Item required per parent Item.

- Qty. Required

The total quantity of the component Item required by the Work Order will be displayed.

- Scrap %

Displayed value represents the allotted Scrap percentage for the component Item when manufacturing the parent Item.

- Qty. Issued

The total quantity of the component Item issued to the Work Order to date will be displayed.

- Qty. to Issue

to Issue: Enter the quantity of the component Item you want to issue to the Work Order.

- UOM

Issue Unit of Measure.

- QOH Before

Total Quantity on Hand prior to the issue will be displayed.

- QOH After

Total Quantity on Hand after the proposed issue will be displayed.

Note

If you are issuing Lot/Serial Items to a Work Order, these cannot be issued automatically from a default Location. You must individually select and then distribute the desired Lot/Serial quantity.

To the far right of the screen, the following buttons are available:

- CANCEL

Closes the screen without issuing any of the selected component material to the selected Work Order, returning you to the application desktop.

- POST

Issues the component Item in the quantity specified.