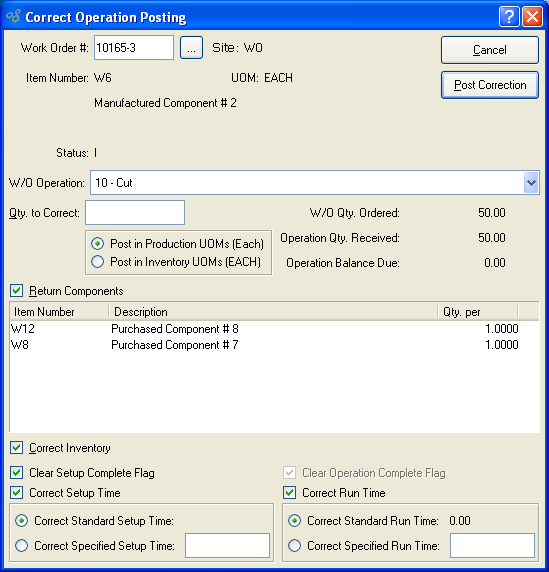

To correct a Work Order Operations posting, select the "Correct Operations Posting" option. The following screen will appear:

When correcting a Work Order Operations posting, you are presented with the following options:

- Work Order #

Enter the Work Order Number of the Work Order whose Operations posting you want to correct.

- Site

Displays Site code automatically when Work Order Number is entered into "Work Order #" field.

- Item Number

Displays Item Number automatically when Work Order Number is entered into "Work Order #" field.

- UOM

Inventory Unit of Measure.

- Status

Displays Work Order Status automatically when Work Order Number is entered into "Work Order #" field.

- Method

Indicates whether selected Work Order is an Assembly or Disassembly Work Order.

- W/O Operation

Select the individual Operation you want to post from the list of Work Order Operations for the specified Item. After selecting an Operation, specify details for that Operation. To correct Operations posting for another Operation, simply select that Operation from the sequential list.

- Qty. to Correct

Enter the quantity you want to correct.

- Post in Production UOMs

Select to post the corrected quantity in Production Units of Measure. Operations may be posted using either the Inventory or Production UOM. In addition, different Operations in a single Bill of Operations may use different Production UOMs. For example, if you are producing soup, you might mix the soup in one Operation using UOM = BATCH. But when canning the soup, the canning Operation might use UOM = CAN. If you post Operations using the Production UOM, the Inventory/Production UOM ratio defined at the Operation level normalizes the posting so that the Inventory impact is recorded using the Inventory UOM.

- Post in Inventory UOMs

Select to post the corrected quantity in Inventory Units of Measure.

- W/O Qty. Ordered

Ordered: Indicates the quantity of material, measures in the Item's Inventory UOM, that the selected Work Order is due to produce.

- Operation Qty. Received

Indicates the quantity, measured in the Item's Inventory UOM, that has been completed by this Operation.

- Operation Balance Due

Indicates the quantity remaining to be produced by the specified Operation.

- Return Components

Components: Select to return components to the Work Order Material Requirements. Option will only be enabled when Work Order Material Requirements are linked to a selected Operation. Only Items whose issue method is "Pull" or "Mixed" will be displayed.

- Correct Inventory

Select of you wish to remove any Inventory issued to stock by the selected Operation. Enabled if the selected Operation is tagged to receive Inventory.

- Clear Setup Complete Flag

Select to clear the setup complete flag.

- Correct Setup Time

Select to correct setup time.

- Correct Standard Setup Time

Select to correct standard setup time.

- Correct Specified Setup Time

Specify the non-standard amount of setup time used. The amount of time entered will be corrected.

- Clear Operation Complete Flag

Select to clear the Operation as complete flag.

- Correct Run Time

Select to correct run time.

- Correct Standard Run Time

Select to correct the standard run time for specified Item.

- Correct Specified Run Time

Specify the non-standard amount of run time used. The amount of time entered will be corrected. The amount of time entered will be posted.

To the far right of the screen, the following buttons are available:

- CANCEL

Closes the screen without posting Operations, returning you to the application desktop.

- POST CORRECTION

Posts the specified Operation using the values entered in the screen.