Manufacturing Buffer Status Reports section.

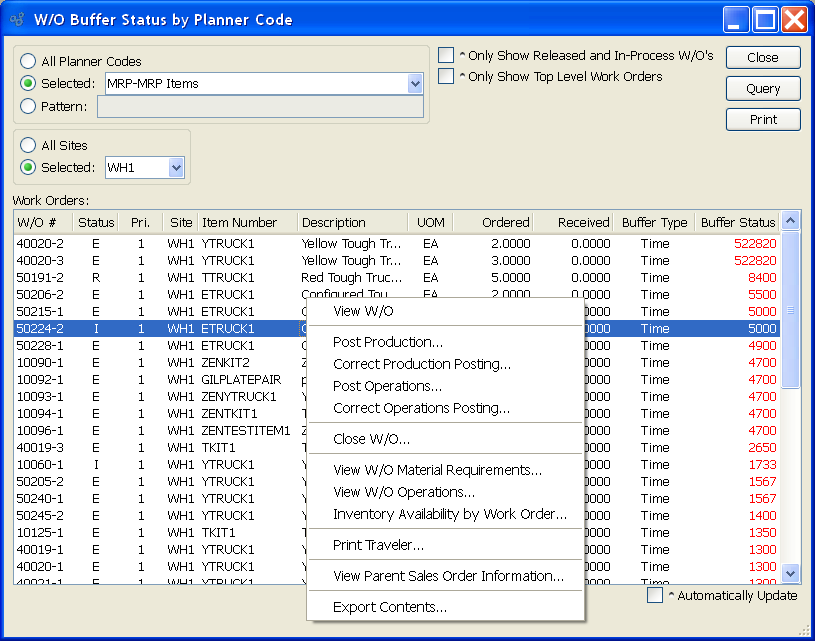

6.6.2.1. Work Order Buffer Status by Planner Code

The Work Order buffer status displays provide information on your

current stock and time buffer levels for those Items having current Work

Orders. Stock buffers apply to make-to-stock Items; whereas time buffers

apply to Items which are make-to-order. Keep in mind that buffer status

information will only be displayed on days when the Constraint Management

system is run. If you find your displays show no information, this probably

means Constraint Management has not been run.

To view Work Order buffer status by Planner Code, select the "Work

Order Buffer Status by Planner Code" option. The following screen will

appear:

Note

When the buffer status for an Item hits 66 or higher, the status

number will become red. By highlighting Items which are "red hot," the

system is informing you which Items should be acted on immediately. The

best remedy for red hot Item Sites is to expedite any associated Work

Orders or Purchase Orders.

When displaying Work Order buffer status by Planner Code, you are

presented with the following options:

- All Planner Codes

Select to display Work Order buffer statuses for all Planner

Codes.

- Selected

Specify Planner Code whose Work Order buffer statuses you want

to display.

- Planner Code Pattern

Enter a Planner Code pattern to select a range of Item Groups.

Refine your search using Regular Expressions.

- All Sites

Select to display Work Order buffer statuses for all

Sites.

- Selected

Specify Site whose Work Order buffer statuses you want to

display.

Note

By default, the display will sort Work Orders by buffer status in

descending order. In other words, Work Orders with the highest buffer

status will appear at the top of the list; Work Orders with the lowest

buffer status will appear at the bottom.

- Only Show Released and In-Process W/O"s

Select to display only released and in-process Work Order

schedules. Selecting this option means only Work Orders whose Status

is released ("R") or in-process ("I") will be displayed.

- Only Show Top Level Work Orders

Select to display only top level Work Orders. Top level Work

Orders are Work Orders that have not been created to meet the

component demands of a parent Work Order.

- Work Orders

Display lists Work Order buffer statuses by Planner Code, using

the specified parameters.

- Automatically Update

Select to automatically update the display every five

minutes.

To the far right and at the bottom of the screen, the following

buttons are available:

- CLOSE

Closes the screen, returning you to the application

desktop.

- QUERY

Select to generate the display, using the specified

parameters.

- PRINT

Runs the report associated with this screen.

Right-clicking on a Work Order in the Work Orders list enables you to

select a number of context-sensitive menu options. If the Work Order's

Status is open "O," the following options will appear when you right-click

on the Work Order:

-

View W/O

Select to view the specified Work Order detail.

-

Explode W/O

Select to explode the specified Work Order. Applies only to

Open Work Orders.

-

Delete W/O

Select to delete the specified Work Order.

-

Reprioritize W/O

Select to change the priority for the specified Work

Order.

-

Reschedule W/O

Select to reschedule the specified Work Order.

-

Change W/O Quantity

Select to change the quantity of the specified Work

Order.

-

Export the data displayed on the screen into a plain-text,

TAB-delimited file. This file may subsequently be imported into a

spreadsheet or other office tool.

If the Work Order's Status is exploded "E," the following options will

appear when you right-click on the Work Order:

-

View W/O

Select to view the specified Work Order detail.

-

Release W/O

Select to release the specified Work Order. Applies only to

Exploded Work Orders.

-

Post Production

Select to post Production for the specified Work Order.

-

Post Operations

Select to post Operations for the specified Work Order.

-

Implode W/O

Select to implode the specified Work Order. Applies only to

Exploded Work Orders.

-

Delete W/O

Select to delete the specified Work Order.

-

View W/O Material Requirements

Select to view Work Order Material Requirements for the

specified Work Order.

-

View W/O Operations

Select to view Work Order Operations for the specified Work

Order.

-

Inventory Availability by Work Order

Select to view Inventory Availability for the specified Work

Order.

-

Print Traveler

Select to print a Traveler for the specified Work

Order.

-

Reprioritize W/O

Select to change the priority for the specified Work

Order.

-

Reschedule W/O

Select to reschedule the specified Work Order.

-

Change W/O Quantity

Select to change the quantity of the specified Work

Order.

-

Export the data displayed on the screen into a plain-text,

TAB-delimited file. This file may subsequently be imported into a

spreadsheet or other office tool.

If the Work Order's Status is released "R", the following options will

appear when you right-click on the Work Order:

-

View W/O

Select to view the specified Work Order detail.

-

Recall W/O

Select to recall the specified Work Order to an Exploded

state. Applies only to Released Work Orders.

-

Post Production

Select to post Production for the specified Work Order.

-

Correct Production Posting

Select to correct Production Posting for the specified Work

Order.

-

Post Operations

Select to post Operations for the specified Work Order.

-

Correct Operations Posting

Select to correct Operations Posting for the specified Work

Order.

-

Close W/O

Select to close the specified Work Order.

-

View W/O Material Requirements

Select to view Work Order Material Requirements for the

specified Work Order.

-

View W/O Operations

Select to view Work Order Operations for the specified Work

Order.

-

Inventory Availability by Work Order

Select to view Inventory Availability for the specified Work

Order.

-

Print Traveler

Select to print a Traveler for the specified Work

Order.

-

Export the data displayed on the screen into a plain-text,

TAB-delimited file. This file may subsequently be imported into a

spreadsheet or other office tool.

If the Work Order's Status is in-process "I," the following options

will appear when you right-click on the Work Order:

-

View W/O

Select to view the specified Work Order detail.

-

Post Production

Select to post Production for the specified Work Order.

-

Correct Production Posting

Select to correct Production Posting for the specified Work

Order.

-

Post Operations

Select to post Operations for the specified Work Order.

-

Correct Operations Posting

Select to correct Operations Posting for the specified Work

Order.

-

Close W/O

Select to close the specified Work Order.

-

View W/O Material Requirements

Select to view Work Order Material Requirements for the

specified Work Order.

-

View W/O Operations

Select to view Work Order Operations for the specified Work

Order.

-

View W/O Material Availability

Select to view Work Order Material Availability for the

specified Work Order.

-

Print Traveler

Select to print a Traveler for the specified Work

Order.

-

Export the data displayed on the screen into a plain-text,

TAB-delimited file. This file may subsequently be imported into a

spreadsheet or other office tool.

If the Work Order is a child Work Order, the following additional

option will appear:

-

View Parent Work Order Information

Select to view the parent Work Order information for the

specified Work Order.

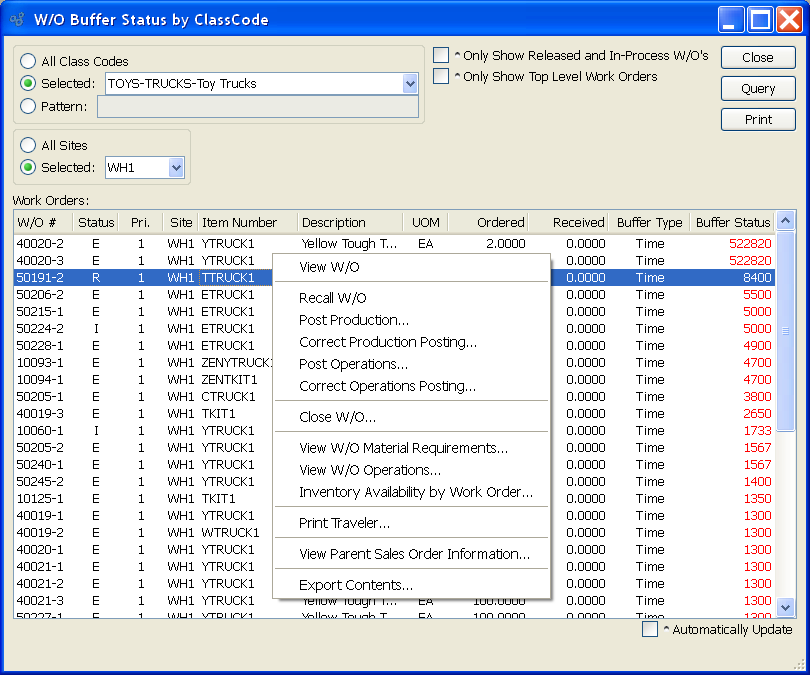

6.6.2.2. Work Order Buffer Status by Class Code

The Work Order buffer status displays provide information on your

current stock and time buffer levels for those Items having current Work

Orders. Stock buffers apply to make-to-stock Items; whereas time buffers

apply to Items which are make-to-order. Keep in mind that buffer status

information will only be displayed on days when the Constraint Management

system is run. If you find your displays show no information, this probably

means Constraint Management has not been run.

To view Work Order buffer status by Class Code, select the "Work Order

Buffer Status by Class Code" option. The following screen will

appear:

Note

When the buffer status for an Item hits 66 or higher, the status

number will become red. By highlighting Items which are "red hot," the

system is informing you which Items should be acted on immediately. The

best remedy for red hot Item Sites is to expedite any associated Work

Orders or Purchase Orders.

When displaying Work Order buffer status by Class Code, you are

presented with the following options:

- All Class Codes

Select to display Work Order buffer statuses for all Class

Codes.

- Selected

Specify Class Code whose Work Order buffer statuses you want to

display.

- Class Code Pattern

Enter a Class Code pattern to select a range of Item Groups.

Refine your search using Regular Expressions.

- All Sites

Select to display Work Order buffer statuses for all

Sites.

- Selected

Specify Site whose Work Order buffer statuses you want to

display.

Note

By default, the display will sort Work Orders by buffer status in

descending order. In other words, Work Orders with the highest buffer

status will appear at the top of the list; Work Orders with the lowest

buffer status will appear at the bottom.

- Only Show Released and In-Process W/O"s

Select to display only released and in-process Work Order

schedules. Selecting this option means only Work Orders whose Status

is released ("R") or in-process ("I") will be displayed.

- Only Show Top Level Work Orders

Select to display only top level Work Orders. Top level Work

Orders are Work Orders that have not been created to meet the

component demands of a parent Work Order.

- Work Orders

Display lists Work Order buffer statuses by Class Code, using

the specified parameters.

- Automatically Update

Select to automatically update the display every five

minutes.

To the far right and at the bottom of the screen, the following

buttons are available:

- CLOSE

Closes the screen, returning you to the application

desktop.

- QUERY

Select to generate the display, using the specified

parameters.

- PRINT

Runs the report associated with this screen.

Right-clicking on a Work Order in the Work Orders list enables you to

select a number of context-sensitive menu options. If the Work Order's

Status is open "O," the following options will appear when you right-click

on the Work Order:

-

View W/O

Select to view the specified Work Order detail.

-

Explode W/O

Select to explode the specified Work Order. Applies only to

Open Work Orders.

-

Delete W/O

Select to delete the specified Work Order.

-

Reprioritize W/O

Select to change the priority for the specified Work

Order.

-

Reschedule W/O

Select to reschedule the specified Work Order.

-

Change W/O Quantity

Select to change the quantity of the specified Work

Order.

-

Export the data displayed on the screen into a plain-text,

TAB-delimited file. This file may subsequently be imported into a

spreadsheet or other office tool.

If the Work Order's Status is exploded "E," the following options will

appear when you right-click on the Work Order:

-

View W/O

Select to view the specified Work Order detail.

-

Release W/O

Select to release the specified Work Order. Applies only to

Exploded Work Orders.

-

Post Production

Select to post Production for the specified Work Order.

-

Post Operations

Select to post Operations for the specified Work Order.

-

Implode W/O

Select to implode the specified Work Order. Applies only to

Exploded Work Orders.

-

Delete W/O

Select to delete the specified Work Order.

-

View W/O Material Requirements

Select to view Work Order Material Requirements for the

specified Work Order.

-

View W/O Operations

Select to view Work Order Operations for the specified Work

Order.

-

Inventory Availability by Work Order

Select to view Inventory Availability for the specified Work

Order.

-

Print Traveler

Select to print a Traveler for the specified Work

Order.

-

Reprioritize W/O

Select to change the priority for the specified Work

Order.

-

Reschedule W/O

Select to reschedule the specified Work Order.

-

Change W/O Quantity

Select to change the quantity of the specified Work

Order.

-

Export the data displayed on the screen into a plain-text,

TAB-delimited file. This file may subsequently be imported into a

spreadsheet or other office tool.

If the Work Order's Status is released "R", the following options will

appear when you right-click on the Work Order:

-

View W/O

Select to view the specified Work Order detail.

-

Recall W/O

Select to recall the specified Work Order to an Exploded

state. Applies only to Released Work Orders.

-

Post Production

Select to post Production for the specified Work Order.

-

Correct Production Posting

Select to correct Production Posting for the specified Work

Order.

-

Post Operations

Select to post Operations for the specified Work Order.

-

Correct Operations Posting

Select to correct Operations Posting for the specified Work

Order.

-

Close W/O

Select to close the specified Work Order.

-

View W/O Material Requirements

Select to view Work Order Material Requirements for the

specified Work Order.

-

View W/O Operations

Select to view Work Order Operations for the specified Work

Order.

-

Inventory Availability by Work Order

Select to view Inventory Availability for the specified Work

Order.

-

Print Traveler

Select to print a Traveler for the specified Work

Order.

-

Export the data displayed on the screen into a plain-text,

TAB-delimited file. This file may subsequently be imported into a

spreadsheet or other office tool.

If the Work Order's Status is in-process "I," the following options

will appear when you right-click on the Work Order:

-

View W/O

Select to view the specified Work Order detail.

-

Post Production

Select to post Production for the specified Work Order.

-

Correct Production Posting

Select to correct Production Posting for the specified Work

Order.

-

Post Operations

Select to post Operations for the specified Work Order.

-

Correct Operations Posting

Select to correct Operations Posting for the specified Work

Order.

-

Close W/O

Select to close the specified Work Order.

-

View W/O Material Requirements

Select to view Work Order Material Requirements for the

specified Work Order.

-

View W/O Operations

Select to view Work Order Operations for the specified Work

Order.

-

View W/O Material Availability

Select to view Work Order Material Availability for the

specified Work Order.

-

Print Traveler

Select to print a Traveler for the specified Work

Order.

-

Export the data displayed on the screen into a plain-text,

TAB-delimited file. This file may subsequently be imported into a

spreadsheet or other office tool.

If the Work Order is a child Work Order, the following additional

option will appear:

-

View Parent Work Order Information

Select to view the parent Work Order information for the

specified Work Order.

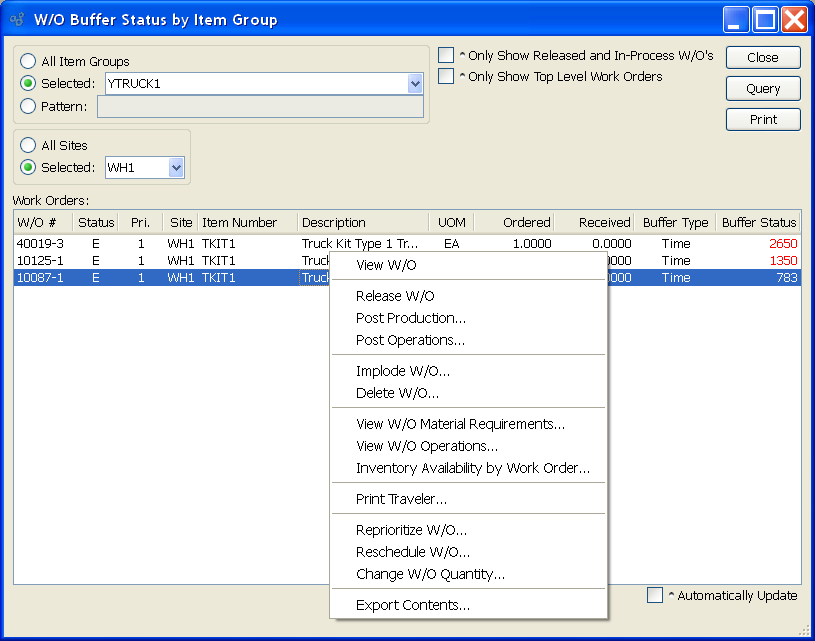

6.6.2.3. Work Order Buffer Status by Item Group

The Work Order buffer status displays provide information on your

current stock and time buffer levels for those Items having current Work

Orders. Stock buffers apply to make-to-stock Items; whereas time buffers

apply to Items which are make-to-order. Keep in mind that buffer status

information will only be displayed on days when the Constraint Management

system is run. If you find your displays show no information, this probably

means Constraint Management has not been run.

To view Work Order buffer status by Item Group, select the "Work Order

Buffer Status by Item Group" option. The following screen will

appear:

Note

When the buffer status for an Item hits 66 or higher, the status

number will become red. By highlighting Items which are "red hot," the

system is informing you which Items should be acted on immediately. The

best remedy for red hot Item Sites is to expedite any associated Work

Orders or Purchase Orders.

When displaying Work Order buffer status by Item Group, you are

presented with the following options:

- All Item Groups

Select to display Work Order buffer statuses for all Item

Groups.

- Selected

Specify Item Group whose Work Order buffer statuses you want to

display.

- Item Group Pattern

Enter an Item Group pattern to select a range of Item Groups.

Refine your search using Regular Expressions.

- All Sites

Select to display Work Order buffer statuses for all

Sites.

- Selected

Specify Site whose Work Order buffer statuses you want to

display.

Note

By default, the display will sort Work Orders by buffer status in

descending order. In other words, Work Orders with the highest buffer

status will appear at the top of the list; Work Orders with the lowest

buffer status will appear at the bottom.

- Only Show Released and In-Process W/O"s

Select to display only released and in-process Work Order

schedules. Selecting this option means only Work Orders whose Status

is released ("R") or in-process ("I") will be displayed.

- Only Show Top Level Work Orders

Select to display only top level Work Orders. Top level Work

Orders are Work Orders that have not been created to meet the

component demands of a parent Work Order.

- Work Orders

Display lists Work Order buffer statuses by Item Group, using

the specified parameters.

- Automatically Update

Select to automatically update the display every five

minutes.

To the far right and at the bottom of the screen, the following

buttons are available:

- CLOSE

Closes the screen, returning you to the application

desktop.

- QUERY

Select to generate the display, using the specified

parameters.

- PRINT

Runs the report associated with this screen.

Right-clicking on a Work Order in the Work Orders list enables you to

select a number of context-sensitive menu options. If the Work Order's

Status is open "O," the following options will appear when you right-click

on the Work Order:

-

View W/O

Select to view the specified Work Order detail.

-

Explode W/O

Select to explode the specified Work Order. Applies only to

Open Work Orders.

-

Delete W/O

Select to delete the specified Work Order.

-

Reprioritize W/O

Select to change the priority for the specified Work

Order.

-

Reschedule W/O

Select to reschedule the specified Work Order.

-

Change W/O Quantity

Select to change the quantity of the specified Work

Order.

-

Export the data displayed on the screen into a plain-text,

TAB-delimited file. This file may subsequently be imported into a

spreadsheet or other office tool.

If the Work Order's Status is exploded "E," the following options will

appear when you right-click on the Work Order:

-

View W/O

Select to view the specified Work Order detail.

-

Release W/O

Select to release the specified Work Order. Applies only to

Exploded Work Orders.

-

Post Production

Select to post Production for the specified Work Order.

-

Post Operations

Select to post Operations for the specified Work Order.

-

Implode W/O

Select to implode the specified Work Order. Applies only to

Exploded Work Orders.

-

Delete W/O

Select to delete the specified Work Order.

-

View W/O Material Requirements

Select to view Work Order Material Requirements for the

specified Work Order.

-

View W/O Operations

Select to view Work Order Operations for the specified Work

Order.

-

Inventory Availability by Work Order

Select to view Inventory Availability for the specified Work

Order.

-

Print Traveler

Select to print a Traveler for the specified Work

Order.

-

Reprioritize W/O

Select to change the priority for the specified Work

Order.

-

Reschedule W/O

Select to reschedule the specified Work Order.

-

Change W/O Quantity

Select to change the quantity of the specified Work

Order.

-

Export the data displayed on the screen into a plain-text,

TAB-delimited file. This file may subsequently be imported into a

spreadsheet or other office tool.

If the Work Order's Status is released "R", the following options will

appear when you right-click on the Work Order:

-

View W/O

Select to view the specified Work Order detail.

-

Recall W/O

Select to recall the specified Work Order to an Exploded

state. Applies only to Released Work Orders.

-

Post Production

Select to post Production for the specified Work Order.

-

Correct Production Posting

Select to correct Production Posting for the specified Work

Order.

-

Post Operations

Select to post Operations for the specified Work Order.

-

Correct Operations Posting

Select to correct Operations Posting for the specified Work

Order.

-

Close W/O

Select to close the specified Work Order.

-

View W/O Material Requirements

Select to view Work Order Material Requirements for the

specified Work Order.

-

View W/O Operations

Select to view Work Order Operations for the specified Work

Order.

-

Inventory Availability by Work Order

Select to view Inventory Availability for the specified Work

Order.

-

Print Traveler

Select to print a Traveler for the specified Work

Order.

-

Export the data displayed on the screen into a plain-text,

TAB-delimited file. This file may subsequently be imported into a

spreadsheet or other office tool.

If the Work Order's Status is in-process "I," the following options

will appear when you right-click on the Work Order:

-

View W/O

Select to view the specified Work Order detail.

-

Post Production

Select to post Production for the specified Work Order.

-

Correct Production Posting

Select to correct Production Posting for the specified Work

Order.

-

Post Operations

Select to post Operations for the specified Work Order.

-

Correct Operations Posting

Select to correct Operations Posting for the specified Work

Order.

-

Close W/O

Select to close the specified Work Order.

-

View W/O Material Requirements

Select to view Work Order Material Requirements for the

specified Work Order.

-

View W/O Operations

Select to view Work Order Operations for the specified Work

Order.

-

View W/O Material Availability

Select to view Work Order Material Availability for the

specified Work Order.

-

Print Traveler

Select to print a Traveler for the specified Work

Order.

-

Export the data displayed on the screen into a plain-text,

TAB-delimited file. This file may subsequently be imported into a

spreadsheet or other office tool.

If the Work Order is a child Work Order, the following additional

option will appear:

-

View Parent Work Order Information

Select to view the parent Work Order information for the

specified Work Order.